The Sintered NdFeB Magnet has the high remanence, high coercive force, high energy product and high performance. It is easily formed into various sizes, and widely used in mini-motors, meters, sensors, sound device, magnetic suspension system, magnetic transmission machine and iatrical apparatus and other applications. It is prone to corrosion in humid environments, It usually need surface treatment according to customer’s requirements to protect magnet. We can offer the coating included: Zinc, Nickel, Silver, Gold-plating, Passivation, Phosphor and Spray Epoxy Resin.

|

>>Magnetic Properties of Sintered NdFeB Magnets: |

|

Magnetic Properties of Sintered NdFeB Magnets |

|

Grade |

Br |

Hcb |

Hcj |

BHmax |

Tw Max |

|

KGs |

mT |

KOe |

KA/m |

KOe |

KA/m |

KJ/m3 |

MGOe |

℃ |

|

N35 |

11.7-12.2 |

1170-1220 |

≥10.9 |

≥868 |

≥12 |

≥955 |

263-287 |

33-36 |

80℃ |

|

N38 |

12.2-12.5 |

1220-1250 |

≥11.3 |

≥899 |

≥12 |

≥955 |

287-310 |

36-39 |

80℃ |

|

N40 |

12.5-12.8 |

1250-1280 |

≥11.4 |

≥907 |

≥12 |

≥955 |

302-326 |

38-41 |

80℃ |

|

N42 |

12.8-13.2 |

1280-1320 |

≥11.5 |

≥915 |

≥12 |

≥955 |

318-342 |

40-43 |

80℃ |

|

N45 |

13.2-13.8 |

1320-1380 |

≥11.6 |

≥923 |

≥12 |

≥ 955 |

342-366 |

43-46 |

80℃ |

|

N48 |

13.8-14.2 |

1380-1420 |

≥11.6 |

≥923 |

≥12 |

≥876 |

366-390 |

46-49 |

80℃ |

|

N50 |

14.0-14.5 |

1400-1450 |

≥10.0 |

≥796 |

≥11 |

≥876 |

382-406 |

48-51 |

80℃ |

|

N52 |

14.3-14.8 |

1430-1480 |

≥10.0 |

≥796 |

≥11 |

≥876 |

398-422 |

50-53 |

80℃ |

|

30M |

10.8-11.3 |

1080-1130 |

≥10.0 |

≥796 |

≥14 |

≥1114 |

223-247 |

28-31 |

100℃ |

|

33M |

11.3-11.7 |

1130-1170 |

≥10.5 |

≥836 |

≥14 |

≥1114 |

247-263 |

31-33 |

100℃ |

|

35M |

11.7-12.2 |

1170-1220 |

≥10.9 |

≥868 |

≥14 |

≥1114 |

263-287 |

33-36 |

100℃ |

|

38M |

12.2-12.5 |

1220-1250 |

≥11.3 |

≥899 |

≥14 |

≥1114 |

287-310 |

36-39 |

100℃ |

|

40M |

12.5-12.8 |

1250-1280 |

≥11.6 |

≥923 |

≥14 |

≥1114 |

302-326 |

38-41 |

100℃ |

|

42M |

12.8-13.2 |

1280-1320 |

≥12.0 |

≥955 |

≥14 |

≥1114 |

318-342 |

40-43 |

100℃ |

|

45M |

13.2-13.8 |

1320-1380 |

≥12.5 |

≥995 |

≥14 |

≥1114 |

342-366 |

43-46 |

100℃ |

|

48M |

13.6-14.3 |

1360-1430 |

≥12.9 |

≥1027 |

≥14 |

≥1114 |

366-390 |

46-49 |

100℃ |

|

50M |

14.0-14.5 |

1400-1450 |

≥13.0 |

≥1033 |

≥14 |

≥1114 |

382-406 |

48-51 |

100℃ |

|

30H |

10.8-11.3 |

1080-1130 |

≥10.0 |

≥796 |

≥17 |

≥1353 |

223-247 |

28-31 |

120℃ |

|

33H |

11.3-11.7 |

1130-1170 |

≥10.5 |

≥836,, |

≥17 |

≥1353 |

247-271 |

31-34 |

120℃ |

|

35H |

11.7-12.2 |

1170-1220 |

≥10.9 |

≥868 |

≥17 |

≥1353 |

263-287 |

33-36 |

120℃ |

|

38H |

12.2-12.5 |

1220-1250 |

≥11.3 |

≥899 |

≥17 |

≥1353 |

287-310 |

36-39 |

120℃ |

|

40H |

12.5-12.8 |

1250-1280 |

≥11.6 |

≥923 |

≥17 |

≥1353 |

302-326 |

38-41 |

120℃ |

|

42H |

12.8-13.2 |

1280-1320 |

≥12.0 |

≥955 |

≥17 |

≥1353 |

318-342 |

40-43 |

120℃ |

|

45H |

13-13.6 |

1300-1360 |

≥12.1 |

≥963 |

≥17 |

≥1353 |

326-358 |

43-46 |

120℃ |

|

48H |

13.7-14.3 |

1370-1430 |

≥12.5 |

≥995 |

≥17 |

≥1353 |

366-390 |

46-49 |

120℃ |

|

30SH |

10.8-11.3 |

1080-1130 |

≥10.1 |

≥804 |

≥20 |

≥1592 |

223-247 |

28-31 |

150℃ |

|

33SH |

11.3-11.7 |

1130-1170 |

≥10.6 |

≥844 |

≥20 |

≥1592 |

247-271 |

31-34 |

150℃ |

|

35SH |

11.7-12.2 |

1170-1220 |

≥11.0 |

≥876 |

≥20 |

≥1592 |

263-287 |

33-36 |

150℃ |

|

38SH |

12.2-12.5 |

1220-1250 |

≥11.4 |

≥907 |

≥20 |

≥1592 |

287-310 |

36-39 |

150℃ |

|

40SH |

12.5-12.8 |

1240-1280 |

≥11.8 |

≥939 |

≥20 |

≥1592 |

302-326 |

38-41 |

150℃ |

|

42SH |

12.8-13.2 |

1280-1320 |

≥12.4 |

≥987 |

≥20 |

≥1592 |

318-342 |

40-43 |

150℃ |

|

45SH |

13.2-13.8 |

1320-1380 |

≥12.6 |

≥1003 |

≥20 |

≥1592 |

342-366 |

43-46 |

150℃ |

|

28UH |

10.2-10.8 |

1020-1080, |

≥9.6 |

≥764 |

≥25 |

≥1990 |

207-231 |

26-29 |

180℃ |

|

30UH |

10.8-11.3 |

1080-1130 |

≥10.2 |

≥812 |

≥25 |

≥1990 |

223-247 |

28-31 |

180℃ |

|

33UH |

11.3-11.7 |

1130-1170 |

≥10.7 |

≥852 |

≥25 |

≥1990 |

247-271 |

31-34 |

180℃ |

|

35UH |

11.8-12.2 |

1180-1220 |

≥10.8 |

≥860 |

≥25 |

≥1990 |

263-287 |

33-36 |

180℃ |

|

38UH |

12.2-12.5 |

1220-1250 |

≥11.0 |

≥876 |

≥25 |

≥1990 |

287-310 |

36-39 |

180℃ |

|

40UH |

12.5-12.8 |

1240-1280 |

≥11.3 |

≥899 |

≥25 |

≥1990 |

302-326 |

38-41 |

180℃ |

|

28EH |

10.4-10.9 |

1040-1090 |

≥9.8 |

≥780 |

≥30 |

≥2388 |

207-231 |

26-29 |

200℃ |

|

30EH |

10.8-11.3 |

1080-1130 |

≥10.2 |

≥812 |

≥30 |

≥2388 |

223-247 |

28-31 |

200℃ |

|

33EH |

11.3-11.7 |

1130-1170 |

≥10.5 |

≥836 |

≥30 |

≥2388 |

247-271 |

31-34 |

200℃ |

|

35EH |

11.7-12.2 |

1170-1220 |

≥11.0 |

≥876 |

≥30 |

≥2388 |

263-287 |

33-36 |

200℃ |

|

38EH |

12.2-12.5 |

1220-1250 |

≥11.3 |

≥899 |

≥30 |

≥2388 |

287-310 |

36-39 |

200℃ |

|

28AH |

10.4-11.0 |

1040-1100 |

≥9.7 |

≥772 |

≥35 |

≥2786 |

207-231 |

26-29 |

220℃ |

|

30AH |

10.8-11.7 |

1080-1170 |

≥10.2 |

≥812 |

≥35 |

≥2786 |

223-255 |

28-32 |

220℃ |

|

33AH |

11.4-12.2 |

1140-1220 |

≥10.7 |

≥851 |

≥35 |

≥2786 |

247-279 |

31-35 |

220℃ |

|

35AH |

11.7-12.5 |

1170-1250 |

≥11.0 |

≥876 |

≥35 |

≥2786 |

263-295 |

33-37 |

220℃ | |

>> Available Coatings of Sintered NdFeB Magnets:

|

Available Coatings (Plating) |

|

Surface |

Coating |

Thickness |

Color |

Resistance |

|

Passivation |

|

1 |

Silver Grey |

Temporary Protection |

|

Nickel |

NiCuNi |

10-20 |

Bright Silver |

Excellent Against Humidity |

|

Zinc |

Zn/3CrZn |

8-20 |

Bright Blue |

Good Against Salt Spray |

|

Tin |

NiCuSn |

15-20 |

Shinny Color |

Excellent Against Humidity |

|

Gold |

NiCuNiAu |

10-20 |

Gold |

Superior Against Humidity |

|

Silver |

NiCuNiAg |

10-20 |

Silver |

Superior Against Humidity |

|

Copper |

NiCu |

10-20 |

Gold |

Temporary Protection |

|

Epoxy |

Epoxy |

15-25 |

Black,Red,Grey |

Excellent Against Humidity& Salt Spray |

|

Zn+Epoxy |

|

NiCuNi+Epoxy |

|

Chemical |

Ni |

10-20 |

Silver Grey |

Excellent Against Humidity |

|

Parylene |

Parylene |

5-20 |

Grey |

Excellent Against Humidity, Salt Spray, Superior Against Solvents, Gases, Fungi and Bacteria, FDA Approved |

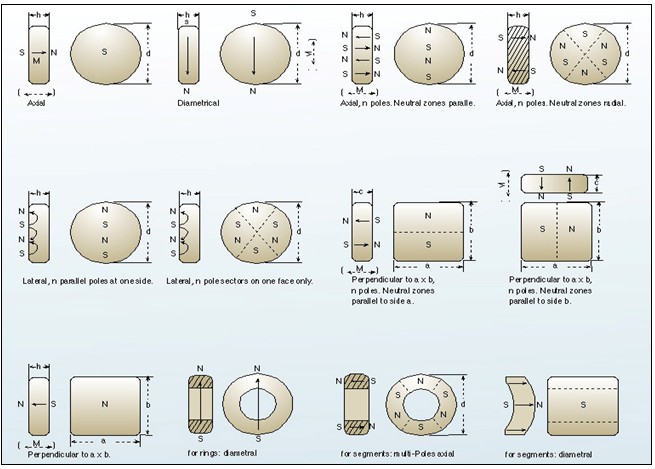

>> Magnetized Direction of Sintered NdFeB Magnets:

|